We can take your design concepts and requirements and give you piece of mind that you have the assurance required to meet regulatory and statutory requirements.

Having both industrial and product design capabilities to offer gives the reassurance that, where appropriate, designs meet both functional and aesthetic objectives.

CAD Design is carried out and enables us and your team to quickly transform new ideas into great products. 3D CAD design is carried out to ensure that costs are kept to a minimum and the time to take designs into production are kept to a minimum.

The key points for our fabrication offering are:

Bending is a manufacturing process that we use to produce angles most commonly in sheet metal.

We have a 100 tonne capacity press brake with a 3100 bed.

Typical products that we make using this process are Guards--conveyors--cladding & boxes such as electrical enclosures and rectangular duct work.

Cutting is the separation of a physical object, into two or more portions, through the application of an acutely directed force.

For metals there are many cutting methods which can be grouped by the physical phenomenon used.

Below is a list of some of the cutting techniques utilised at Bespoke Metal Engineering Ltd:

-- Sawing -- Drilling -- Shearing -- Punching

-- Stamping -- Grinding -- plasma cutting

Drilling is a cutting process that uses a drill bit to cut or enlarge a hole of circular cross-section in solid materials.

The drill bit is a rotary cutting tool, often multipoint. The bit is pressed against the work piece and rotated at rates from hundreds to thousands of revolutions per minute.

This forces the cutting edge against the work piece, cutting off chips (swarf) from the hole as it is drilled.

We can drill many different materials to customers specifications.

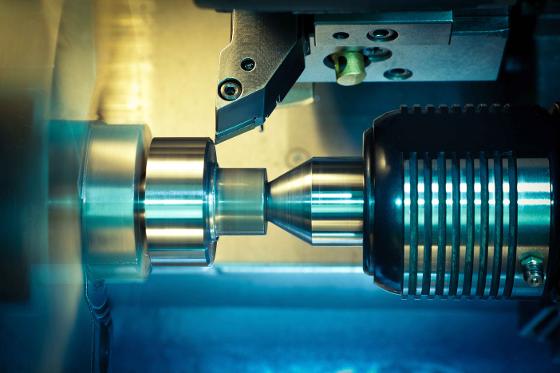

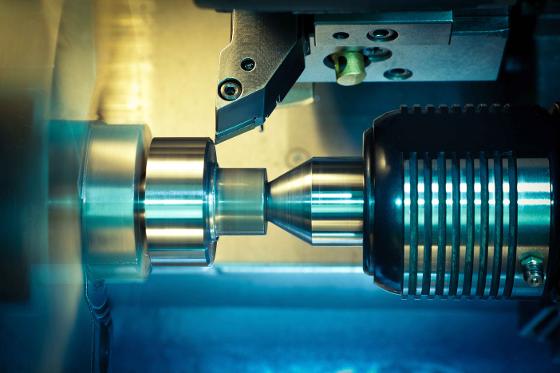

We have different size Mills and Lathes which gives us more capabilities to do lots of different jobs like shafts,

Notching is a process which cuts stock without the formation of chips or the use of burning or melting. Strictly speaking, if the cutting blades are straight the process is called shearing.

The most commonly sheared materials are in the form of sheet metal or plates.

We have a number of Notching machines at Bespoke Metal Engineering Ltd each with different capabilities, which gives us great flexibility.

Welding is a fabrication process that joins materials, in our case metals, by causing coalescence (to join into a single mass or whole).

This is often done by melting the work pieces and adding a filler material to form a pool of molten material (the weld pool) that cools to become a strong joint, with pressure sometimes used in conjunction with heat, or by itself, to produce the weld.

At Bespoke Metal Engineering Ltd we use different methods to weld mild steel, stainless steel and aluminium, titanium, brass, bronze,copper,

The welding techniques we use primarily are:

-- MMA -- MIG -- TIG

© Copyright Bespoke Metal Engineering Ltd

Make a free website with Yola